Tereck Mining Technology Co.Limited

- HOME|

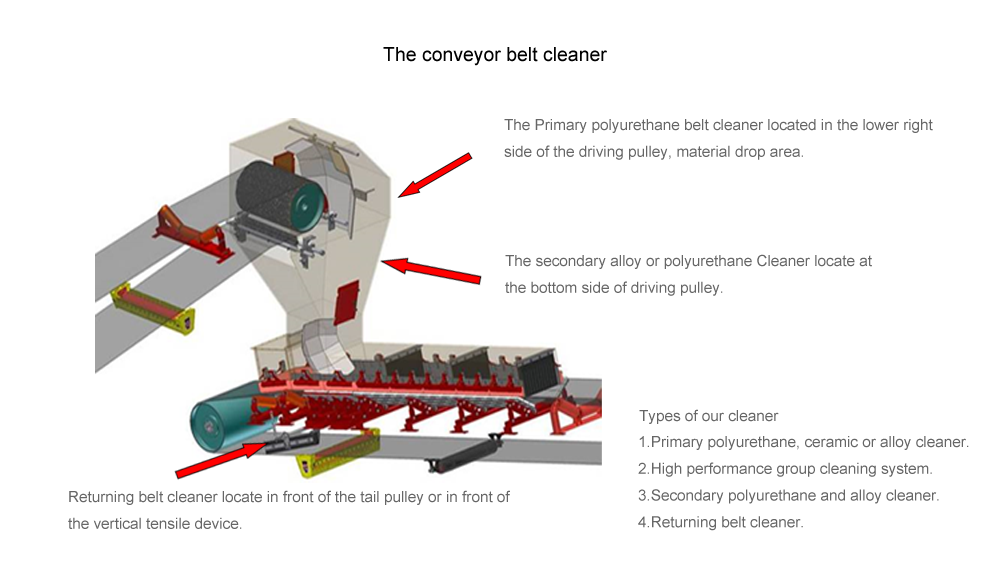

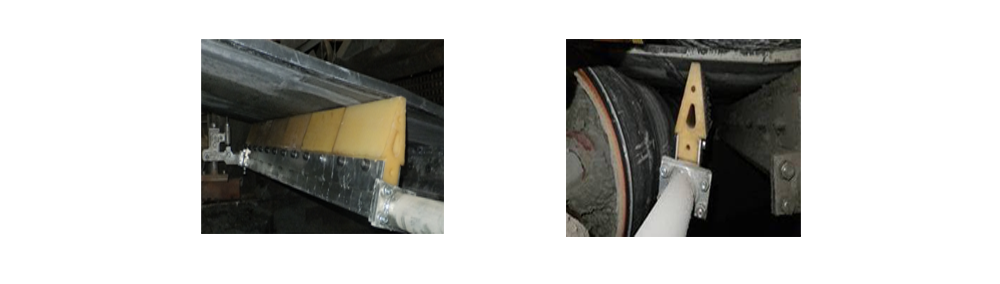

The cleaner blades use polyurethane, metal or ceramic material, low friction, high wear resistance and high strength. Blade surface is flat, cleaning work is stable, especially for large material viscosity, extremely corrosion condition. The cleaner blades use subsection, embedded design, very convenient for installation, replacement and maintenance. The elastic mechanism ensured that the contact with the belt has uniform and stable pressure, to achieve perfect shaving performance, effectively improved the service life of the conveyor belt.

SQZ High performance group cleaning system is consist of three devices include: atomizing water cleaning device, high pressure gas cleaning device, and polyurethane or alloy blade cleaner.First, high pressure water will clean the material on the belt and inside damaged belt area, also wet the material sticking on the belt.

Then the high pressure gas device will clean up all wet material;

Finally, the high efficiency polyurethane or metal blade scraper will clean up all remaining material on the belt.

【Why we use tungsten alloy blade】Conveyor belt carrying surface always has subtle and high viscosity material, like a long beard, the secondary cleaner like a razor, only blades are sharp enough could remove the material. The sharp blade won't damage the conveyor belt with the right angle, but it will efficiently clean and protect the conveyor belt.

The different type blade utilized in different section, suitable for extreme working conditions or old belt cleaning. Hollow blade design, buffer is good for the belt. Supports use embedded trough structure, blades are easy to install and replace. Polyurethane blades will not damage the belt.

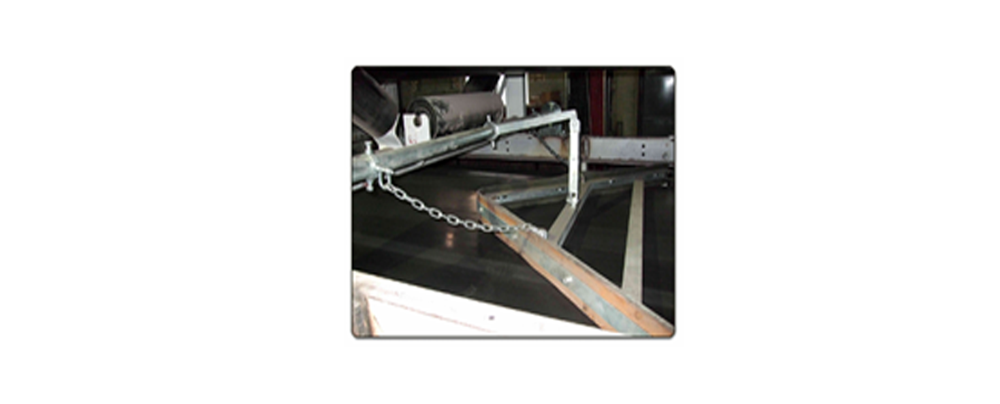

Return belt cleaner is used to clean the non working belt surface, effectively prevent the material fall into the tail between the pulley and belt, and damage them.

【characteristics】Blades are top wear-resisting rubber plate, abrasion resistance, corrosion resistance. Parallel structure frame will make sure the cleaner connect closely with the conveyor belt, based on belt position and blade abrasion status, the cleaner will automatically adjust the location, clear material efficient, simple structure and easy maintenance. After installation, the two wings extend to the most suitable angle and sliding on the return belt to clean the material.

CopyRight © 2021 Tereck Mining Technology Co.Limited all rights rerserved 沪ICP备15031775号-1